Restoring Vintage Loudspeakers

Inexpensive tweaks that can improve the presentation of your speakers.

IntroductionWe at Madisound are often asked about what is the best way to upgrade older or vintage loudspeakers. In fact there are many ways to improve on sound, whether perceived as too dull, too bright or boomy, or not enough dynamics, for some examples. Loudspeakers vary greatly in build quality, from the drive units, cabinets, and wiring to the internal electrical parts. Rather than spending thousands of dollars to achieve results, we will suggest some simpler and less expensive solutions involving some straightforward modifications that almost anyone can make. The purpose of this guide is not to address loudspeaker design or crossover theory but to rather offer some inexpensive tweaks that can improve the presentation of your speakers. Over time, loudspeaker components tend to decay. Many loudspeakers over twenty years old contain parts that have either decayed over time or were of poor quality in the first place. Organic materials in the drivers can dry rot while many types of capacitors can dry out and lose their effectiveness. Upgrading woofers for example can increase the bass response and power handling of your system. However once you are at the point of replacing all drivers and electrical components, it may not be practical and you might be better off just starting from scratch, which could save time and money in the long run. It really depends at that point how much you like the original cabinets, and what condition they are in and if they used good quality materials. Madisound offers many brands of replacement loudspeakers and crossover parts. How difficult these modifications will be depends on how easy it is to gain access to the cabinet interior. Access is usually gained by removing the largest drive-unit. Again, if your goal is to upgrade the loudspeakers with higher quality drivers, you should first consider whether the quality of the cabinets and crossovers is worth the cost of the new drivers. It may be more cost-effective to build a new loudspeaker system. Upgrade ChecklistUpgrade or replace crossover parts especially hi-pass capacitors Upgrade or replace bad loudspeaker drivers Inspect damping and insulation Inspect wiring and terminals Optimize placement of stands and minimize room reflections Crossover ComponentsMany older crossovers used cheaper parts such as electrolytic caps which tend to lose their effectiveness over time. Non-polar electrolytics are known to age or dry out over time and adhesives can lose their grip.

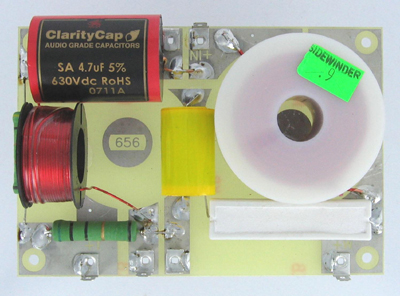

The critical circuitry on a passive crossover is essentially the components that are in *series* with the drive units. Upgrading to better parts in the signal path will improve overall resolution and transparency of the network, resulting in better performance of the loudspeaker. Important to note: it is the components in series with the drivers that are the important ones to look at for upgrading. Suggested upgrades include the Mundorf and ClarityCap brands, which make excellent upgrade for hi-pass caps on tweeters. The Goertz copper foil inductors are ideal for low-pass inductors. Please see our web site for more detail on these brands.

That may be an issue if it is an older speaker that you are updating. Once you know the value of a component, that is the resistor, capacitor or inductor, you should be able to buy a replacement. Replacing crossover parts is fairly straightforward in most cases. First you must remove the existing component, typically hardwired to each other or soldered to the back of the speaker terminals or mounted on a circuit board. The new components are then soldered in position. Keep in mind the better grade parts tend to be physically larger due to higher working voltages and thicker film. Always ensure you have room on the original circuit board and inside the loudspeaker, if they are internally mounted, as most are. Recommended capacitor brands: Mundorf or ClarityCap SA capacitors in series, and Solen, ClarityCap PX or Bennic in parallel. Sometimes the component values will be clearly marked but if not, you will need a network schematic for the crossover.

Drive UnitsIt is possible in many cases to upgrade to better quality loudspeaker drivers. However, once you go beyond simply replacing a tweeter or woofer to a completely new driver complement, the original crossover network, being designed for different drivers, is unlikely to integrate the new drivers properly. At that point, you are perilously close to a complete rebuild. No longer a simple upgrade at that point! Variables that affect driver replacement include basket size, cone or dome materials, voltage sensitivity, impedance, and so on. Please refer to our Madisound retrofits page for general guidelines on woofer replacement. Midranges and tweeter replacement tends to be more complicated. Sometimes it is possible and practical to repair the surrounds of the original woofers. It is best to consult with one of our salespersons if you are unsure about this. Cabinet BracingThis may not always be practical, especially on smaller cabinets, but nevertheless consider adding bracing as a possible upgrade. Typically adding internal bracing will improve stability and reduce box resonance. Most large subwoofer enclosures are internally braced for stability. Internal cross-bracing becomes more important as the box volume increases. Damping MaterialsThere are really two things to look at here. The first is the cabinet’s internal *lining* and the second is the loose fill material in the primary woofer cavity. It is not unusual for older or vintage loudspeakers to be poorly insulated by modern standards. Cheap fiberglass or other materials can be easily replaced with more absorptive products. Madisound recommends beginning with a 5/8" thick foam sheet for internal lining. These sheets can easily be cut to size and installed with spray adhesive. A higher-tech material made in the U. K. is called Deflex Panel, a specially formulated polymer designed to absorb shock and vibration, minimize cabinet resonance, and help eliminate standing waves. These products can be used in conjunction with each other or exclusively. Basically, it’s not rocket science. The better lined the box, the better your results. The rear wall behind the largest drivers is critical to damp, as that is where the large back wave from the drivers wants to reflect or splash, muddying your bass response. For loose fill, typically one-half pound per cubic foot of internal volume is a good guideline especially for subwoofers. Small loudspeakers may only need a few handfuls behind the woofer. We recommend Acousta-Stuf or Wool for this purpose. You must listen to the loudspeaker to try to determine whether it is under-damped, that is boomy-sounding or resonant, versus over-damped, that is dull/flat/ lifeless. This is highly subjective of course. A subwoofer box simulator like Bass Box Pro can be helpful to determine the effects of fill quantity on bass response. Madisound's damping materials. WiringUpdating cheap, generic internal cable is fairly simple and can give good results in conjunction with other upgrades. Supra Classic cable from Sweden is a cost-effective cable solution, featuring tin-plated OFC copper with a PVC jacket. We use this cable extensively for Madisound kits and recommend this brand for wiring upgrades for all loudspeaker applications. Your signal path does not end at the speaker either, of course. Supra is good for external wiring as well and available in a variety of gauges and jacket types, whatever your application. Cable does not sound inherently better or worse in and of itself but its effect on results may be dramatic. Good cable should be low in resistance and inductance, and reasonably low in capacitance. Keep cable runs as short as possible and avoid looping excess cable as this may increase inductance. What is important in speaker cables is how you terminate them. You want to make certain that you have the best connection of the cable to your amp and loudspeaker to minimize contact resistance. Which brings us to the next point, terminals. Common sense is required when it comes to the physical weight pulling on tweeter and midrange terminals. There is really no need for 12 AWG or heavier cable on a tweeter or small midrange. TerminalsYour signal path is only as good as its weakest link. Why spend good money on audiophile cable and drivers, only to funnel your sound through an ultra-cheap $0.25 plastic spring terminal? Upgrading to good quality metal binding posts can make a difference. Mundorf and WBT offer some extremely high-end posts. Yung is a popular brand and makes plastic terminal plates with ¾ binding post spacing. Loose binding posts can also be purchased on our web site. Get rid of those plastic tabs and put in some good quality copper or brass posts. Bi-Wiring and Bi-AmpingBi-wiring refers to using a single amplifier connected to a woofer and a midrange/tweeter separately on a speaker. Often the low-pass and hi-pass sections will be on separate circuit boards. There is no clear evidence that bi-wiring improves sound quality but if you have the means to bi-wire, you can try it and see if it works in your system. Note that some crossover designs cannot be split for bi-wiring. It should be clear either way when you physically examine them. Bi-amping involves each driver in the system being powered by a separate channel of the power amplifier, or two separate power sources with one amplifier connected to a woofer and the other to a midrange/tweeter. In many cases this does significantly improve sound quality. Often two cheaper amplifiers used in a bi-amping arrangement can outperform a single expensive amplifier. Stands and Room PlacementIn general, it is best to avoid placing loudspeakers in corners or near walls, especially side walls. Listener location greatly affects matters as well. Placement in a given room typically requires moving the loudspeakers around to find the best place for them. In general, placing loudspeakers further away from walls, especially rear walls, tends to reduce bass output and improve imaging and vice versa. In some cases you will find loudspeakers designed to be placed near rear walls, but that may not work in your room. Once you think you've found the best position you need to consider how the speakers are placed on the stands. Try coupling the speaker to the stand with speaker spikes. If placing the loudspeakers away from reflective surfaces does not prove sufficient, consider treating the room with absorptive and/or diffusive materials as follows. Room DeadeningOne of the most critical aspects of audio reproduction- the listening room itself- is often overlooked. However this tends to be a difficult variable to control or change. A simple hand clap can be a way to very roughly gauge how much room decay and echoing there is. The shape and dimensions greatly affect sound in a listening room. The rigidity and mass of surface areas are also important in observing how a given room responds. A listening room with rigid and massive walls, floor and ceiling typically results in better bass response from the loudspeaker. Some have gone so far as to reinforce existing drywall with additional sheet-rock and so on, easier in new construction of course. Improving interior surfaces within the listening environment can enhance low frequency detail, unify the sound stage, and improve overall accuracy. Reflections can be a major issue. For example, if the room is too lively due to midrange and high frequency reflections, try adding sound traps or other acoustic control materials like diffusers. SummaryBegin by upgrading/replacing any bad or obsolete crossover parts. Pay close attention to hi-pass capacitors. Next, look at any bad loudspeaker drivers and replace or repair as necessary. While you are inside the cabinet, inspect damping, insulation, wiring and terminals. Consider bi-wiring to improve power. Once the loudspeaker is functioning, optimize placement of stands and minimize room reflections to create an ideal listening environment. By Joshua Biernbaum, April 2009 |